Silica gel, chemical formula: mSiO2 • nH2O, appears as slightly transparent white solid substance. It belongs to genus amorphous. Silica is a highly active, porous material with the internal surface area being large. The specific surface area per g silica can reach above 450 m2. Therefore, it has strong absorption capability on the liquid or gas. Silica gel can’t be dissolve in water, not soluble in other solvents except hydrofluoric acid and strong alkali.

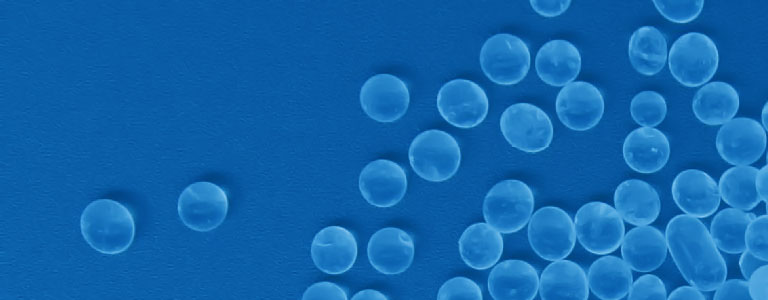

The commercially available solid gel silica has spherical and irregular, two kinds of shapes. According to the pore size, it can be divided into the fine-pore silica gel (with average pore size of less than 1.5 ~ 2.0nm) and coarse pore gel silica (with average pore size of greater than 4.0 ~ 5.0nm). There is another kind of discoloration gel silica containing cobalt chloride with anhydrous cobalt chloride exhibiting blue color. However, after absorbing water, the hydrated cobalt chloride will exhibit pink color with returning back to blue after drying. According the change of the color during dehydration and hydration of cobalt chloride, we can know moisture absorption condition of the silica gel. The pink silica gel has no absorbent capacity, but after thermal dehydration, it will have its color return back to blue and get its absorbent capacity restored.

The silica gel can be manufactured through the reaction between water glass and sulfuric acid, and further gelling, washing, desalting, amidation, drying and screening.

The reaction is as follows:-

nNa2O • mSiO2 + nH2SO4 → mSiO2 • nH2O + nNa2SO4. General industrial silica gel has a mechanical strength of 85 to 95%, water content being below 2% and the moisture absorption rate of 25 to 30%.

Gel silica is mainly used for gas absorption or drying, liquid dehydration and liquid chromatography, also used as catalysts or catalyst carrier. The textile industry uses it as sizing agent. Pore silica gel is mainly used for the drying and purification of gas, the dehydration and purification of organic product, also used as a supported carrier. Coarse-pore gel silica is mainly used to process the macromolecular protein contained in the beer as well as the drying of gas and liquid and defogging as well as dehumidification of gas upon high humidity, as the catalyst and catalyst carrier in the petrochemical industry. Discoloration gel is mainly used to indicate the relative humidity of airtight packaging, precision instruments and the inner space of instrument as well as being used for the moistureproof maintenance of precision instrumentation.

Advantages of silica gel as a desiccant:-

1-Silica gel has many other properties that recommend it as a desiccant.

2-Our silica gel can adsorb up to one third of its own weight in water vapour. This adsorption efficiency of silica gel is approximately 35% greater that typical desiccant clays, utilization of silica gel the preferred choice where weight or efficiency are important factors.

3-Silica gel has an almost indefinite shelf life if stored in airtight conditions.

4-Silica gel can be regenerated and reused if required. Gently heating silica gel will drive off the adsorbed moisture and leave it ready for reuse.

5-Silica gel is a very inert material, it will not normally attack or corrode other materials and with the exception of strong alkalis and hydrofluoric acid is itself resistant to attack.

6-Silica gel is non-toxic and non-flammable.

7-Silica gel is most frequently and conveniently used packed in a breathable sachet or bag. These are available in a wide range of sizes suitable for use with a wide range of applications.

Adsorption Capacity:-

In general, the water vapor adsorption capacity of Silica gel greatly increases with a rise in relative humidity. Factors such as temperature and flow rate can affect the dynamic capacity of the Silica gel.

Selective Adsorption:-

Silica Gel will selectively adsorb compounds of differing molecular weights. In the liquid phase, compounds of high polarity at more readily adsorbed.

Water (most readily adsorbed):-

1-Alcohols

2-Aromatics

3-Di-Olefins

4-Olefins

5-Paraffins (least readily adsorbed)

Dynamic Adsorption is the process by which the Silica Gel removes an impurity (such as water) from a continuously flowing gas stream. The use of Silica gel in a drying column can produce exit gas with a dew point of 100°F.

How to regenerate (Re-Dry) Silica Gel ?

There are two methods used for re-drying ( regeneration) of silica gel. One method uses the oven, and the other uses the microwave. Before you use either method please read the all the safety precautions described below.

1. Oven Drying Method :

This drying method of silica gel gives the best results even though it takes longer. Set the oven for 120 0C. Place the silica gel in an appropriate container and dry the silica gel until it turns medium blue. The oven drying method takes approximately 1-1/2 hours per quart of silica gel. One quart of silica gel equals weighs approximately 850 grams.

2. Microwave Drying Method :

In this method place the silica gel in an appropriate container and set the microwave power to the medium to medium high setting. Dry silica gel for approximately 3 to 5 minutes and inspect the color change in silica gel crystals. If the silica gel has not dried, stir it with a spoon and heat it for another 3 to 5 minutes. Stir the silica gel mass each time it is inspected. Approximate drying time is 8 to 12 minutes per half kilogram of silica gel. The actual heating times will vary according to the type of microwave. You may set the power setting on high but please be careful not to overheat the silica gel crystals.

For More Information Please Email Us :- sales@toponedry.com